For this project, I applied systems simulation techniques to analyze and optimize the supply chain of a hypothetical fashion brand.

What I Did:

- Problem Identification:

- The company faced delays in delivering new clothing collections to customers.

- The bottlenecks in the supply chain were unclear, affecting efficiency.

- Data Collection & Modeling:

- I gathered and analyzed key historical data, including production times, demand fluctuations, and cost factors

- I defined the critical variables affecting supply chain efficiency.

- Simulation Development & Analysis:

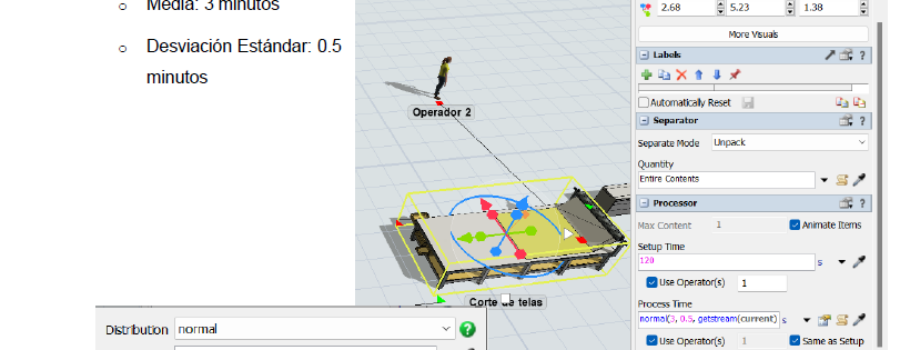

- Built a discrete-event simulation model of the production process.

- Ran three scenarios (pessimistic, intermediate, and optimistic) to evaluate system performance under different conditions.

- Identified key bottlenecks in fabric cutting and sewing stages.

- Analyzed warehouse inefficiencies leading to excess inventory buildup.

- Findings & Optimization Strategies:

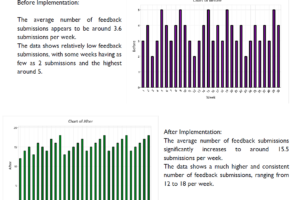

- Reduced processing time in the cutting and sewing stages by over 15% in the optimized scenario.

- Improved synchronization between production and distribution to minimize delays.

- Proposed workflow adjustments to better allocate resources and enhance efficiency.

The simulation demonstrated how strategic process improvements could increase production efficiency, reduce delays, and enhance the supply chain’s responsiveness to demand.